Discover our range of sustainable nonwovens!

Our new range of nonwovens offers the perfect combination of sustainability and functionality. With a selection of tear-away and cut-away stabilizers in different weights, our Green Line nonwovens are suitable for a variety of applications: from delicate blouses and stretchy T-shirts to jackets, jeans, and (fake) leather. Our range includes very soft nonwovens for maximum comfort, as well as nonwovens with special properties that make them excellent for sports wear and functional clothing.

What makes the new nonwovens a sustainable choice?

The stabilizers in the Green Line range contribute to more sustainability in textile finishing in different ways: Some nonwovens are made from recycled polyester, others from natural fibers, and still others are biodegradable or compostable. Most nonwovens also score sustainability points with short delivery routes and CO2 reduction thanks to production in the EU. The nonwovens are certified with renowned standards such as Ökotex, DIN standards, GRS, or PEFC and FSC, so you can work with a good conscience.

Order samples now!

Together with you we want to find out which embroidery backings best meet your requirements for sustainability and functionality. Order samples of our new nonwovens and put them to the test. We look forward to your feedback! With your experience, we can decide which nonwovens to include in our standard range

Order samples

Prices upon request

You have tested one of our new nonwovens and want to use it in your production? Contact our customer service at +49 6027 2008 20 or send your inquiry to service@gunold.de

Inquire now

Sustainable tear-away nonwovens - for lighter, fine fabrics to medium-weight fabrics

Sustainable tear-away nonwovens - for heavy, sturdy fabrics

Sustainable cut-away nonwovens - for medium-weight to heavy, sturdy fabrics

2350W-SAMPLE

- Cut-away

- Colour: white

- Weight: 50 g/m2

- Compostable*

more details

*under industrial conditions

2380W-SAMPLE

- Cut-away

- Colour: white

- Weight: 80 g/m2

- Compostable*

more details

*under industrial conditions

Order samples

You would like to get to know our new nonwovens better and get an impression of their texture and structure? You would like to put our sustainable stabilizers to the test? You can easily order our brochure with small samples of all nonwovens or individual sample sheets for embroidery tests via the contact form. We are also happy to provide further advice - just give us a call. We look forward to your inquiry!

+49 6027 2008 20

Details on our Green Line of sustainable nonwovens

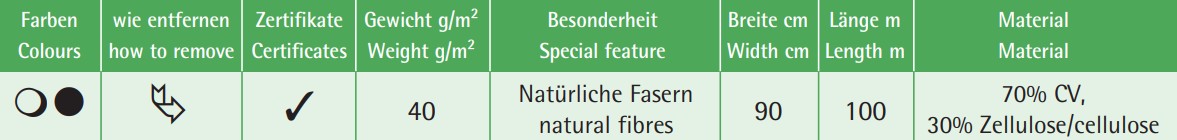

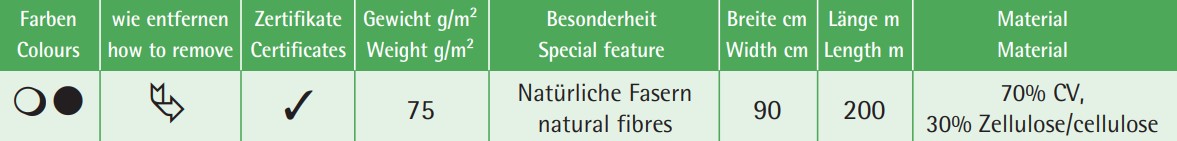

2140S-SAMPLE / 2140W-SAMPLE

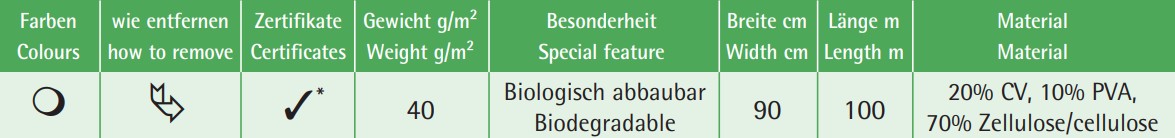

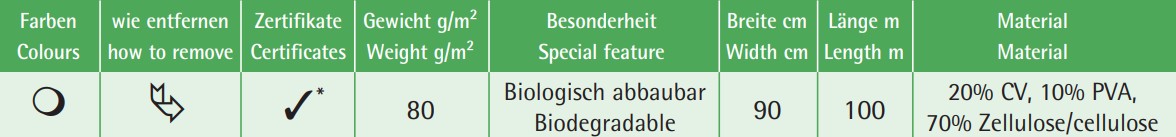

2240W-SAMPLE

The soft character makes this nonwoven an all-rounder. The product composition is what makes this nonwoven so interesting: 10% polyvinyl alcohol is added to the natural fibres viscose/cellulose. This is what makes this product unique. Polyvinyl alcohol (PVA) dissolves completely in water and makes the nonwoven residue in the textile soft and pleasant. The fleece is recommended for use on shirts, blouses, underwear, etc. Tested according to DIN 4872* and to be certified according to Ökotex Standard 100, PK1 in 2025 - this makes this nonwoven truly ecological.

*DIN 84872: Studies show that textiles release tiny fibre residues during washing, which sewage treatment plants are unable to filter out sufficiently. In this way, they enter ecosystems and pollute the environment. Synthetic fibres pose the greatest risk because they are particularly durable and non-biodegradable. Until now, there has been no method for determining the environmental impact of such fibre residues. DIN SPEC 4872, published in February 2023, closes this gap: For the first time, it makes it possible to test, systematically evaluate and compare the biodegradability of textiles or fibres of textile origin. The standard therefore makes a decisive contribution to combating the problem of microplastics in the textile industry. It can be used as a basis for more targeted product development and a general optimisation of the product portfolio in order to avoid further environmental pollution.

Determine Environmental Compatibility: The content of the DIN SPEC is a standardised method that can be used to classify textiles with regard to their fibre release during the washing process. The document describes which equipment and reagents are required for the test procedure and how textile abrasion can be measured and analysed during washing. The method can then be used to classify textiles in terms of fibre release, biodegradability and ecotoxicity. This makes it possible to determine exactly how environmentally friendly they are. The standard can be used for all types of textiles, regardless of their chemical composition - including, for example, textile fabrics such as fleeces, woven, knitted or crocheted fabrics. The DIN SPEC 4872 ‘Test method for textiles - Determination of fibre release during washing and the degree of aerobic degradation in an aqueous medium taking into account ecotoxicity’ is available for free download from DIN Media at www.dinmedia.de.

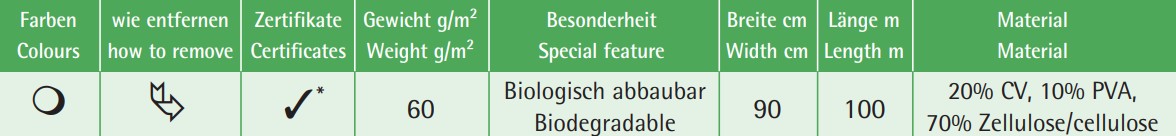

2260W-SAMPLE

*DIN 84872: Studies show that textiles release tiny fibre residues during washing, which sewage treatment plants are unable to filter out sufficiently. In this way, they enter ecosystems and pollute the environment. Synthetic fibres pose the greatest risk because they are particularly durable and non-biodegradable. Until now, there has been no method for determining the environmental impact of such fibre residues. DIN SPEC 4872, published in February 2023, closes this gap: For the first time, it makes it possible to test, systematically evaluate and compare the biodegradability of textiles or fibres of textile origin. The standard therefore makes a decisive contribution to combating the problem of microplastics in the textile industry. It can be used as a basis for more targeted product development and a general optimisation of the product portfolio in order to avoid further environmental pollution.

Determine Environmental Compatibility: The content of the DIN SPEC is a standardised method that can be used to classify textiles with regard to their fibre release during the washing process. The document describes which equipment and reagents are required for the test procedure and how textile abrasion can be measured and analysed during washing. The method can then be used to classify textiles in terms of fibre release, biodegradability and ecotoxicity. This makes it possible to determine exactly how environmentally friendly they are. The standard can be used for all types of textiles, regardless of their chemical composition - including, for example, textile fabrics such as fleeces, woven, knitted or crocheted fabrics. The DIN SPEC 4872 ‘Test method for textiles - Determination of fibre release during washing and the degree of aerobic degradation in an aqueous medium taking into account ecotoxicity’ is available for free download from DIN Media at www.dinmedia.de.

2675S-SAMPLE / 2675W-SAMPLE

2280W-SAMPLE

Very strong, stable nonwoven, paper-like feel. In addition to the viscose/cellulose blend of the fibres, 10% polyvinyl alcohol is added. This makes the product unique, as polyvinyl alcohol (PVA) dissolves completely in water. The backing residue after embroidery stabilises the embroidery for a long time and the colour, which is not pure white, makes it almost unnoticeable. The stabiliser is a good choice for embroidery applications on solid fabrics such as jackets and caps. Certification according to Ökotex Standard 100, PK 1 will take place in 2025; certification according to DIN 4872* is available and makes the stabiliser verifiably ecological. A major plus in terms of the ecological aspect is the fact that the nonwoven is manufactured in the EU.

*DIN 84872: Studies show that textiles release tiny fibre residues during washing, which sewage treatment plants are unable to filter out sufficiently. In this way, they enter ecosystems and pollute the environment. Synthetic fibres pose the greatest risk because they are particularly durable and non-biodegradable. Until now, there has been no method for determining the environmental impact of such fibre residues. DIN SPEC 4872, published in February 2023, closes this gap: For the first time, it makes it possible to test, systematically evaluate and compare the biodegradability of textiles or fibres of textile origin. The standard therefore makes a decisive contribution to combating the problem of microplastics in the textile industry. It can be used as a basis for more targeted product development and a general optimisation of the product portfolio in order to avoid further environmental pollution.

Determine Environmental Compatibility: The content of the DIN SPEC is a standardised method that can be used to classify textiles with regard to their fibre release during the washing process. The document describes which equipment and reagents are required for the test procedure and how textile abrasion can be measured and analysed during washing. The method can then be used to classify textiles in terms of fibre release, biodegradability and ecotoxicity. This makes it possible to determine exactly how environmentally friendly they are. The standard can be used for all types of textiles, regardless of their chemical composition - including, for example, textile fabrics such as fleeces, woven, knitted or crocheted fabrics. The DIN SPEC 4872 ‘Test method for textiles - Determination of fibre release during washing and the degree of aerobic degradation in an aqueous medium taking into account ecotoxicity’ is available for free download from DIN Media at www.dinmedia.de.

2350W-SAMPLE

- Low moisture absorption with a high capillary effect, making it suitable for sportswear and functional clothing.

- Low flammability makes the nonwoven interesting for flame-retardant fabrics.

- In addition, the strength-to-weight ratio is relatively high, which is interesting for high stitch count designs.

**DIN EN 13432: DIN EN 13432 is a European standard that deals with the compostability and biodegradability of products. This means that, under certain conditions, they can be broken down into carbon dioxide, water and biomass within six months.

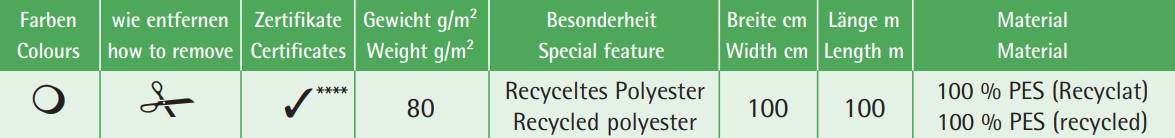

2880W-SAMPLE

Very strong, durable cut-away nonwoven with embossed structure, paper-like feelCut-away nonwovens are always the best choice in terms of stabilisation. The nonwoven remains on the reverse side until the end of the textile‘s use and stabilises the textile, even after frequent wearing, washing and ironing. The stabiliser is perfect for firm fabrics, but also for large, high stitch count embroidery motifs. Certified according to GRS ****, the stabiliser is subject to constant monitoring and the recycled polyester is a good way of recycling raw materials.

****GRS: GRS is an international, voluntary, fully established product standard that specifies requirements for the independent certification of recycled materials, chain of custody, social and environmental practices and chemical restrictions. GRS is designed to meet the needs of companies that want to verify the recycled content of their (finished and intermediate) products and ensure that social, environmental and chemical regulations are met in production. The aim of the Global Recycled Standard is to define requirements for the correct specification of substances and materials used along with correct working conditions.

2380W-SAMPLE

- Low moisture absorption with a high capillary effect, making it suitable for sportswear and functional clothing.

- Low flammability makes the nonwoven interesting for flame-retardant fabrics.

- In addition, the strength-to-weight ratio is relatively high, making it interesting for high stitch count motifs.

**DIN EN 13432: DIN EN 13432 is a European standard that deals with the compostability and biodegradability of products. This means that, under certain conditions, they can be broken down into carbon dioxide, water and biomass within six months.