Needles

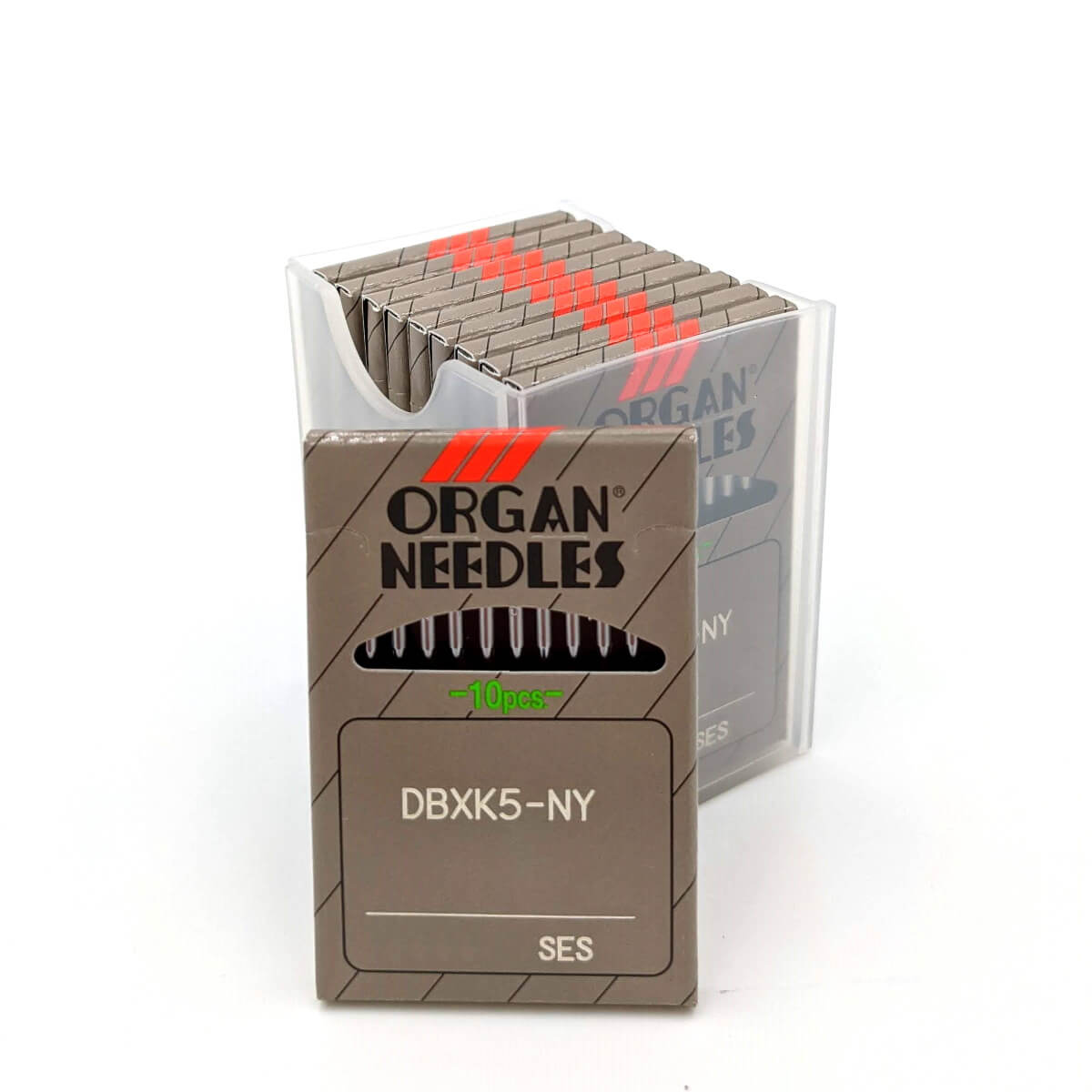

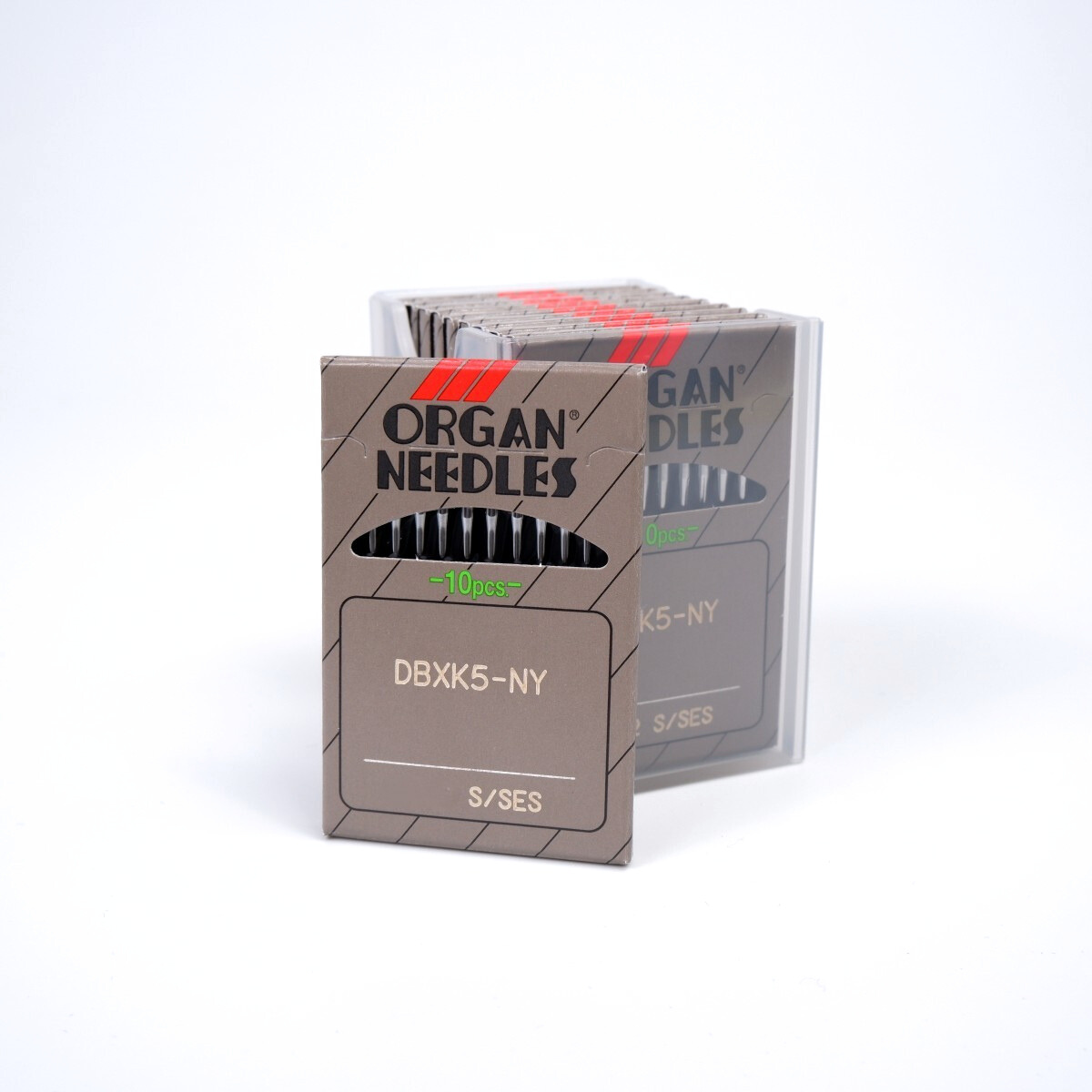

The standard embroidery needle - DBxK5-NY 75/11 (S) SES

A needle for (almost) everything

Almost 90% of all embroidery projects can easily be accomplished with this standard needle, with absolutely perfect stitch results. It is the ideal needle for different thread strengths (40 and 30) and it facilitates knotting and hassle-free threading during thread change.

Th needle system needs to match the machine

Of course, the embroidery needle must also match the machine type. The embroidery machine manufacturers therefore specify which needle systems can be used.

The most important distinction is DBxK5 (round shank) & HAx1 or 130/705H (flat shank).

The needle system in industrial machine embroidery is the round shank (DBxK5 or DBx7ST with extra large needle eye).

Overview Needles

Another crucial detail on the embroidery needle is the point!

Pointed round tips (R) are ideal for firm fabrics, but would damage fine stitches and tear the fabric. That's why there are ball point that don't penetrate the fabric, but glide past the fibers.

Which needle point do I need

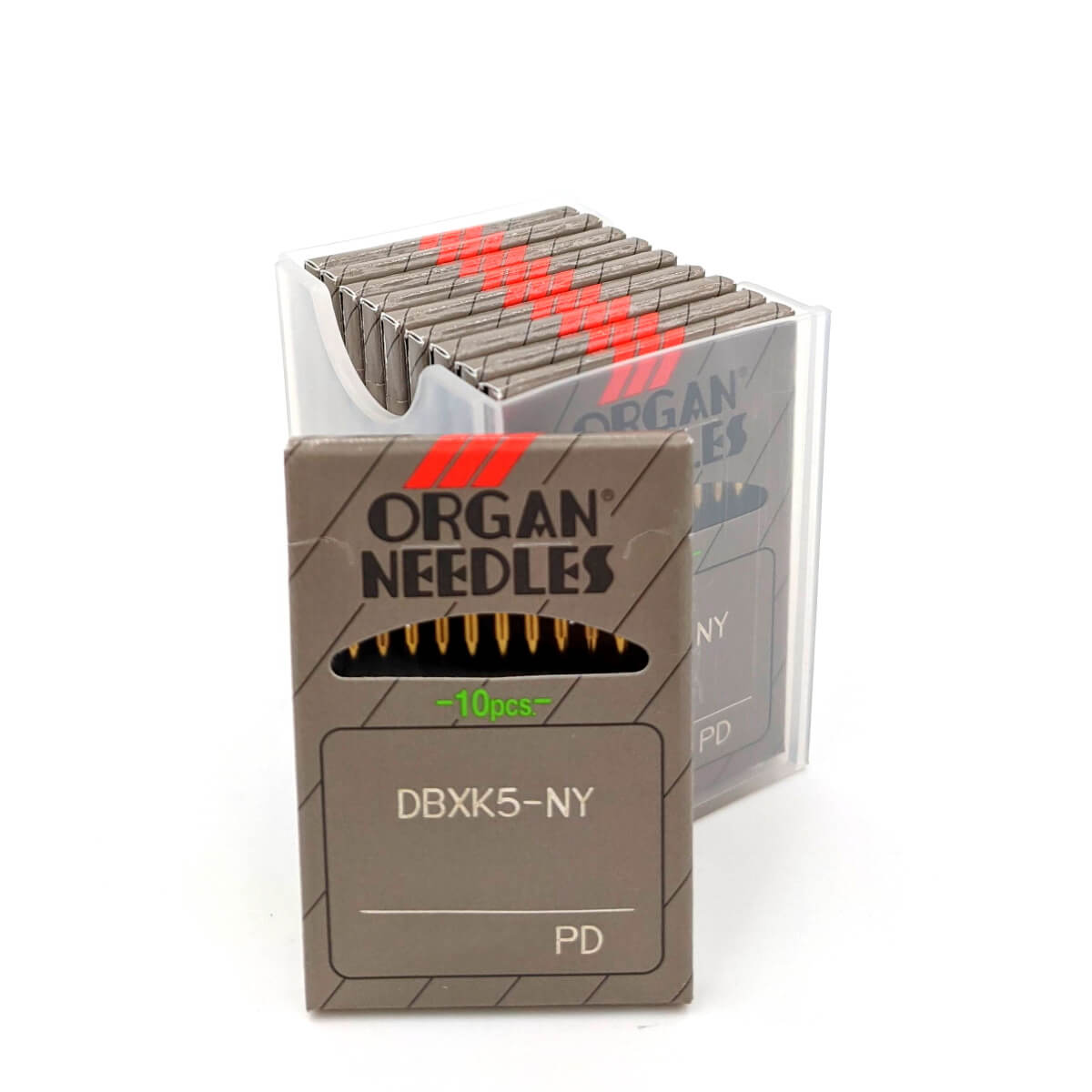

(R): The needle with a regular round point is suitable for tightly woven fabrics such as denim, twill, corduroy, ...

(S): The light/medium ball point is the standard needle point for light and heavy fabrics, dense knitwear, fleece and terry cloth. Economical if the materials to be embroidered change frequently.

(B): The needle with a medium/large ball point is suitable for loose knitwear, knitted fabrics and thick sweatshirt fabrics. The large ball point pushes the fibers apart and guarantees clean embroidery on loosely knitted fabric.

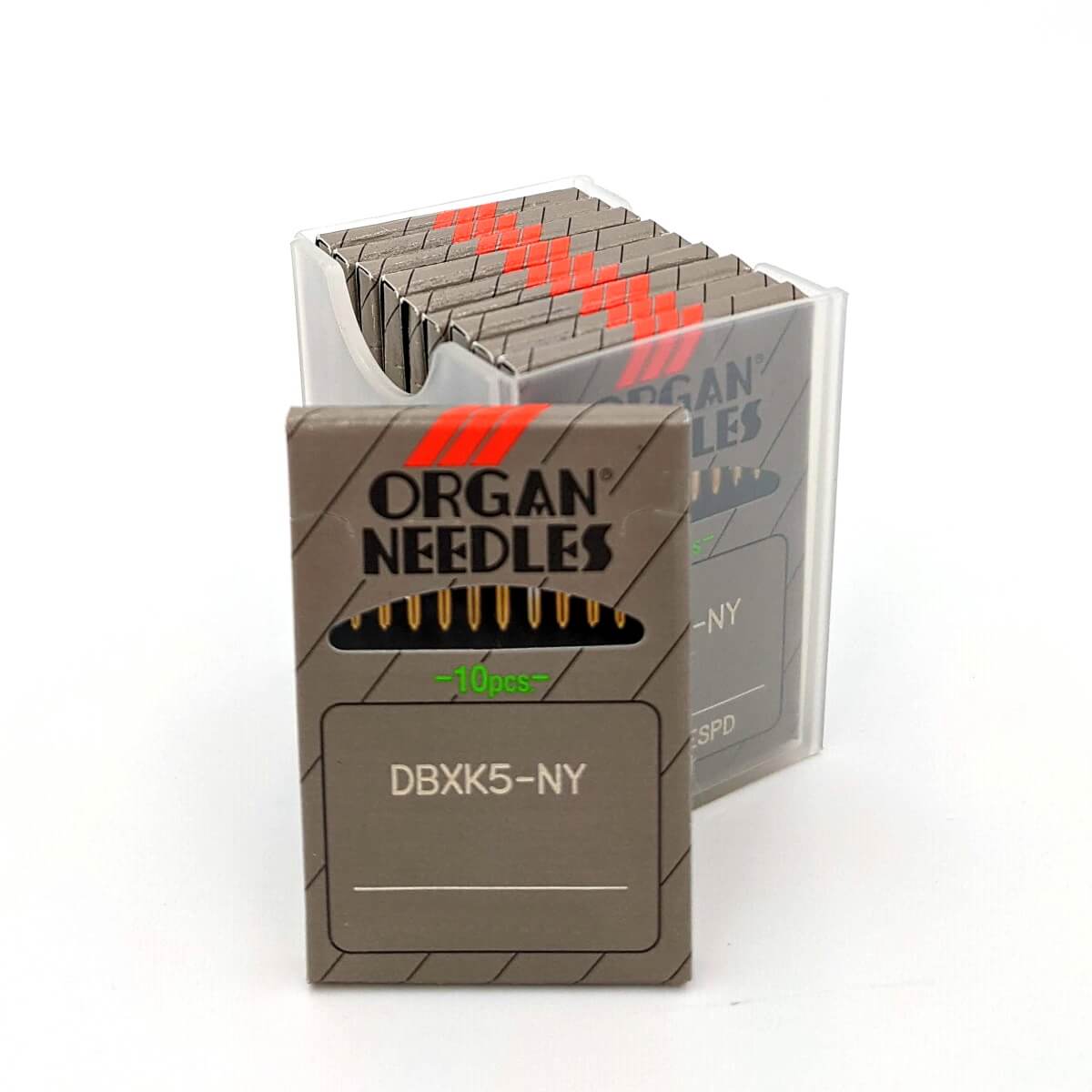

(Q): This specially shaped point (round point with small ball point - also referred to as RG by other needle manufacturers) prevents damage to the needle point as it avoids contact with the rotating hook. The extra fine ball point is also beneficial for preventing the upper thread from breaking. With multi-head embroidery machines, the needle point often touches the upper thread during the work process. Needle point that are too sharp cut the upper thread - not so with the special "Q-ball point" needle.

Infos Needles

It's all about the needle!

At first you have to pay attention to the fabric and embroidery thread - the right needle is absolutely crucial for the perfect embroidery result!

The fabric determines the needle point, the embroidery thread determines the needle size.

Fewer thread breaks, minimization of skipped stitches and robust durability guarantee a trouble-free production process and precise embroidery - even with unusual effect threads. This requires an absolutely intact embroidery needle - we therefore recommend replacing the embroidery needle after approx. 8 hours.

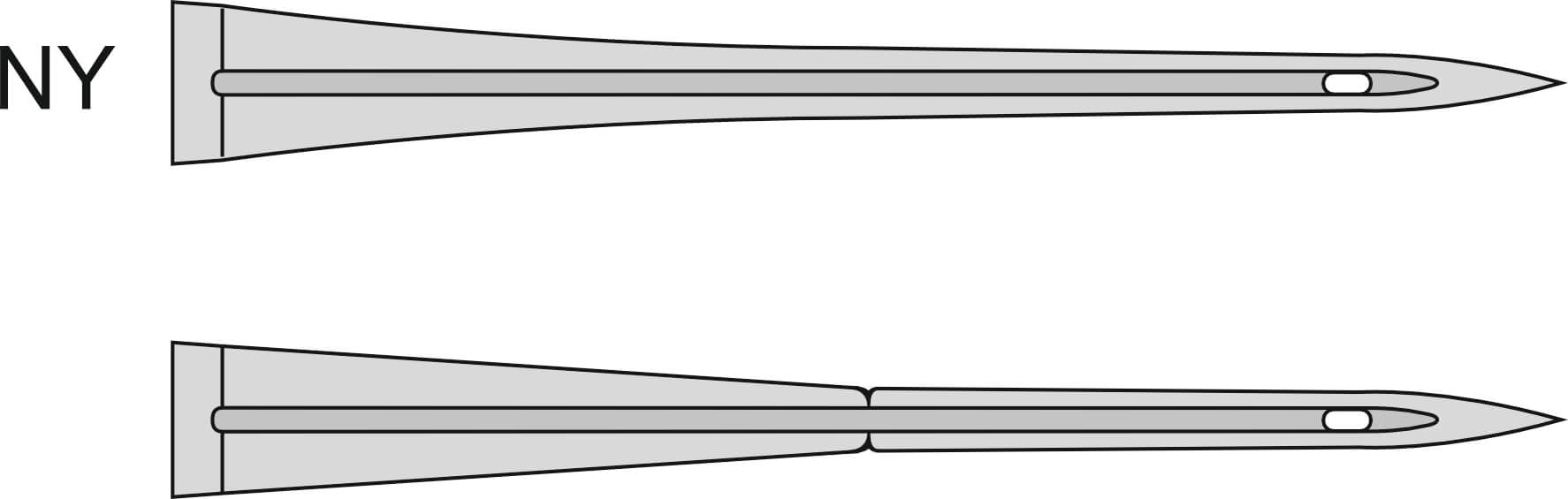

Why DBxK5 - NY

The NY needle is an advanced version of a conventional needle. Compared to a conventional needle, it has an evenly cone-shaped shaft – see drawing.

The needle’s NY shape reduces needle breakage during the embroidery process, resulting in higher productivity.

- Improved thread passage thanks to larger needle’s eye.

- Minimising skipped stitches and less needle breakage thanks to the special, infinitely cone-shaped shaft – the NY shape